Since 3D printing can be cheaper, faster and closer to markets than conventional manufacturing, MARii has considered the technology through an all-in-one workshop, named Malaysia Additive Manufacturing Technology Centre (MAMTEC), in the effort of bringing out a renaissance of manufacturing in Malaysia.

In Malaysia, the manufacturing industry is facing several challenges to remain competitive in relative to the other countries. Adoption to Industry 4.0 is a must and for Automotive, E&E Transportation & Mobility Industry to advance, the core focus should be towards Additive Manufacturing (AM) or better known as three-dimensional (3D) printing.

AM creates an interesting alternative to fill the void from conventional manufacturing which has reached its limits. The major advantages of 3D AM are flexible design, rapid prototyping, print on demand, strong and lightweight parts, fast design and production, minimising waste, cost effective, environmentally friendly and pandemic resilience.

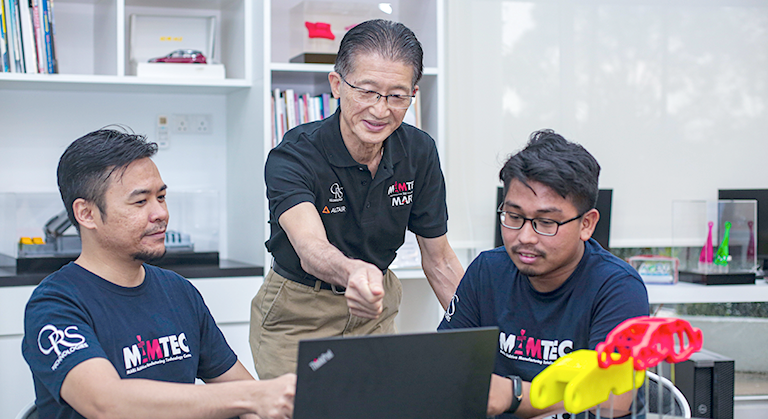

With more than 30 vendors involved, MAMTEC has all of their participants to propose one part from their products to be re-engineered for betterment. Every single parts were to be analyzed and optimized using provided tools and provided software, also having the end products printed using the Kings SLA 3D Printer.

Softwares provided for all MAMTEC’s participants (e.g. CATIA v5, Altair, Materialise, Shining 3D and Geomagic Design X) has assisted the pre-processing, on-processing and the post-processing of the A to Z production process. With MAMTEC’s objective of achieving a well re-engineered products, supervision from the right experts like certified trainers and instructors has became one of the main contributions throughout this program. One of the big practical challenges of printing larger 3D printed parts is spatial. This hybrid workshop has been conducted at its best, easing the designers to get their dimension precised.