GE as the World’s Largest ‘Additive’ Machine

General Electric (GE) has been advancing additive manufacturing (AM) technologies for over 20 years. Recent events include the launch of two Open Invitation manufacturing quests, that have invited entrepreneurs, companies and institutions to offer their solutions to two challenges; to testing of the LEAP-1A engine, with additively manufactured fuel nozzles.

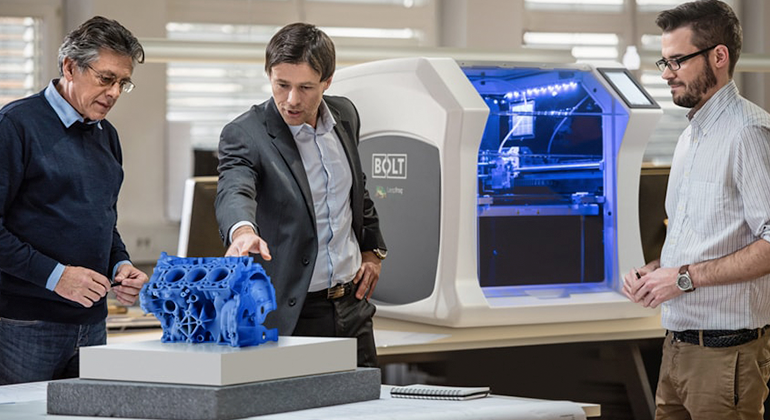

Continuing the quest for greater insight about additive manufacturing, AMazing® turned to GE. The search yielded an in-depth interview with two distinguished leaders from GE, Greg Morris and Todd Rockstroh, Ph.D. Literally. GE Additive, a new GE business dedicated to supplying 3D printers, materials and engineering consulting services, announced today it is developing the world’s largest laser-powered 3D printer that prints parts from metal-powder.

The printer will be able to make parts that fit inside a cube with 1-meter sides. “The machine will 3D print aviation parts suitable for making jet engine structural components and parts for single-aisle aircraft,” said Mohammad Ehteshami, vice president and general manager of GE Additive. “It will also be applicable for manufacturers in the automotive, power, and oil and gas industries.”

As the Business Development Leader for Additive Manufacturing at GE Aviation, Greg Morris develops the roadmap and strategy for additive technologies within GE Aviation. Todd Rockstroh, consulting engineer at GE Aviation, has been with GE Aviation for 27 years and is an award-winning engineer focusing on special process control, laser material processing and smart machining.