GE as the World’s Largest ‘Additive’ Machine

General Electric (GE) has been advancing additive manufacturing (AM) technologies for over 20 years. Recent events include the launch of two Open Invitation manufacturing quests, that have invited entrepreneurs, companies and institutions to offer their solutions to two challenges; to testing of the LEAP-1A engine, with additively manufactured fuel nozzles.

Continuing the quest for greater insight about additive manufacturing, AMazing® turned to GE. The search yielded an in-depth interview with two distinguished leaders from GE, Greg Morris and Todd Rockstroh, Ph.D. Literally. GE Additive, a new GE business dedicated to supplying 3D printers, materials and engineering consulting services, announced today it is developing the world’s largest laser-powered 3D printer that prints parts from metal-powder.

The printer will be able to make parts that fit inside a cube with 1-meter sides. “The machine will 3D print aviation parts suitable for making jet engine structural components and parts for single-aisle aircraft,” said Mohammad Ehteshami, vice president and general manager of GE Additive. “It will also be applicable for manufacturers in the automotive, power, and oil and gas industries.”

As the Business Development Leader for Additive Manufacturing at GE Aviation, Greg Morris develops the roadmap and strategy for additive technologies within GE Aviation. Todd Rockstroh, consulting engineer at GE Aviation, has been with GE Aviation for 27 years and is an award-winning engineer focusing on special process control, laser material processing and smart machining.

MAMTEC as the Training Headstart

Since 3D printing can be cheaper, faster and closer to markets than conventional manufacturing, MARii has considered the technology through an all-in-one workshop, named Malaysia Additive Manufacturing Technology Centre (MAMTEC), in the effort of bringing out a renaissance of manufacturing in Malaysia.

In Malaysia, the manufacturing industry is facing several challenges to remain competitive in relative to the other countries. Adoption to Industry 4.0 is a must and for Automotive, E&E Transportation & Mobility Industry to advance, the core focus should be towards Additive Manufacturing (AM) or better known as three-dimensional (3D) printing.

AM creates an interesting alternative to fill the void from conventional manufacturing which has reached its limits. The major advantages of 3D AM are flexible design, rapid prototyping, print on demand, strong and lightweight parts, fast design and production, minimising waste, cost effective, environmentally friendly and pandemic resilience.

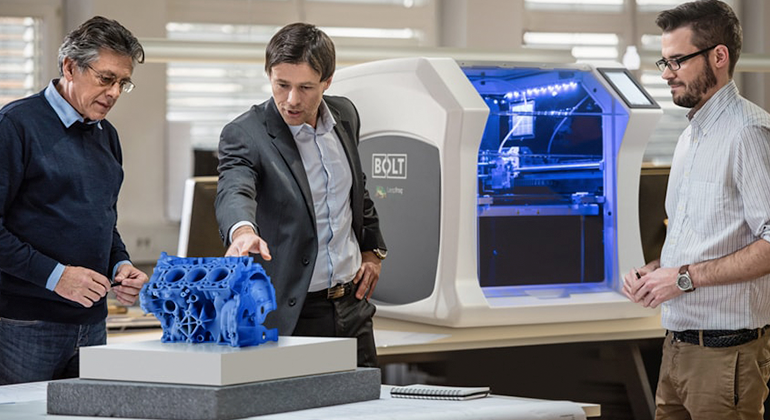

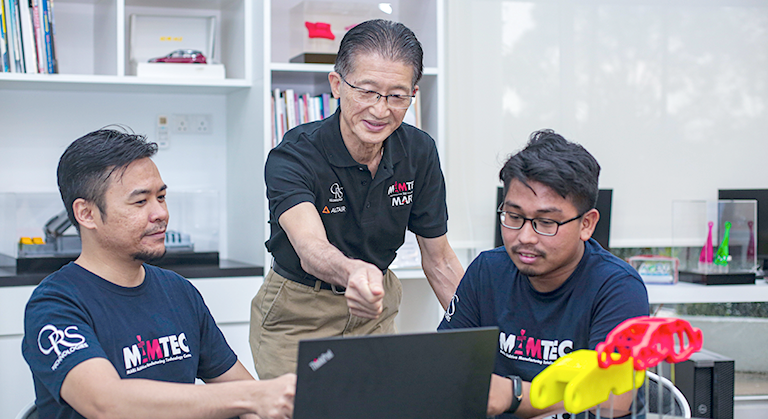

With more than 30 vendors involved, MAMTEC has all of their participants to propose one part from their products to be re-engineered for betterment. Every single parts were to be analyzed and optimized using provided tools and provided software, also having the end products printed using the Kings SLA 3D Printer.

Softwares provided for all MAMTEC’s participants (e.g. CATIA v5, Altair, Materialise, Shining 3D and Geomagic Design X) has assisted the pre-processing, on-processing and the post-processing of the A to Z production process. With MAMTEC’s objective of achieving a well re-engineered products, supervision from the right experts like certified trainers and instructors has became one of the main contributions throughout this program. One of the big practical challenges of printing larger 3D printed parts is spatial. This hybrid workshop has been conducted at its best, easing the designers to get their dimension precised.

Airbus bring 3D into serial production

But why is 3D printing so important? Weight reduction is the holy grail of aerospace engineering: Every kilogram saved prevents 25 tons of CO2 emissions during the lifespan of an aircraft. Parts produced by additive layer manufacturing (ALM), also known as 3D printing, weigh up to 55 per cent less while reducing raw material used by up to 90 per cent. Decarbonisation is the reason why the aerospace industry and Airbus are leading the charge in 3D printing. The speed at which these parts can be manufactured through 3D printing gives less overstock and overhead when creating these customized pieces.

Direct production with Additive Manufacturing had a crucial benefit for Airbus: the lead time. For small-batch series and customized parts, additive technologies offer a drastically faster time-to-market than conventional manufacturing as prior tool-production is not required.

The panels are Airbus’ first cabin parts with full bionic design certification, a successful result of Airbus’ ongoing efforts to optimize part weight. Compared with the original design, intended for conventional production methods, the 3D-printed panels are 15% lighter. In conventional manufacturing, additional complexity would mean higher cost. However, with 3D Printing, complex internal structures like lattices do not create additional cost. Airbus was therefore able to realize lightweight bionic panels and achieve the optimal mass for the component.

The progress made by the aerospace industry highlights the technology’s potential for manufacturing in the EU. With one caveat: Assuming that Europe can quickly build on its technological leadership in this exciting new area.

Future of Automotive Production

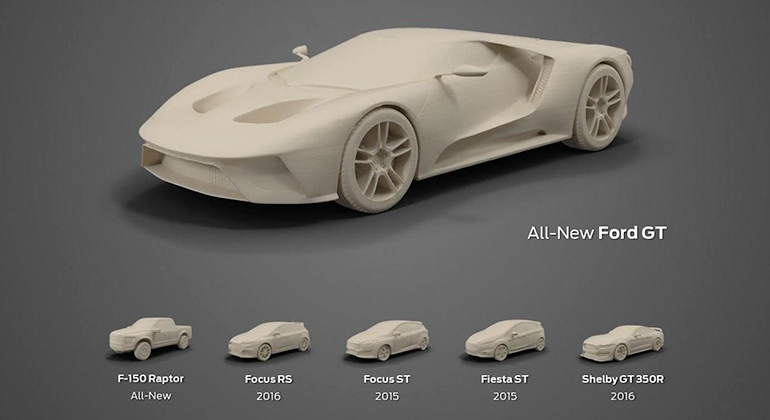

3D printing will also be a central focus of the facility. Unsurprising, considering Ford has been an early champion of 3D printing — having bought the third 3D printer ever made in 1988.

Today, the company now extensively uses 3D printing as part of its product development and is exploring ways to integrate the technology into its production lines. The Advanced Manufacturing Center will play a key role, already housing 23 industrial 3D printers.

3D printing is important to Ford for several reasons. First, speed to market can be cut down significantly via the technology. Product development cycles for some auto makers have been roughly halved relative to the not so distant past. Printing parts also reduces the transportation and logistics costs related to suppliers. Lastly, 3D printing has the potential to open the floodgates of customization in an industry that has long been geared toward mass, standardized production.

3D printing at Ford is not new. Over the past 5 years, the company has made over 700,000 parts using the technology, saving an estimated $200 million. Put differently, Ford touches “a significant portion of the vehicle with 3D printing now,” according to an expert in Ford’s manufacturing division.

With 25 years’ industry experience, Harold Sears is the Technical Leader of Additive Manufacturing Technologies at Ford. We recently spoke with Sears to learn more about how the company is innovating 3D printing for the automotive industry.