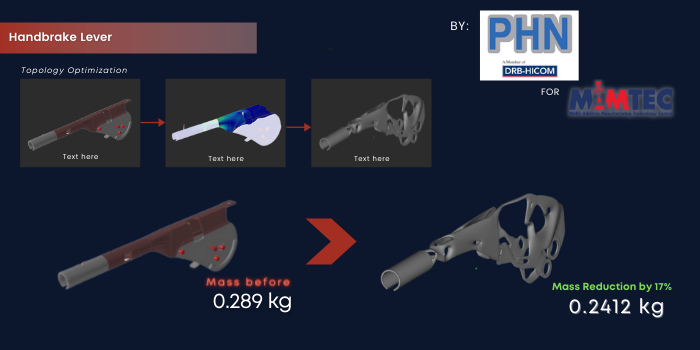

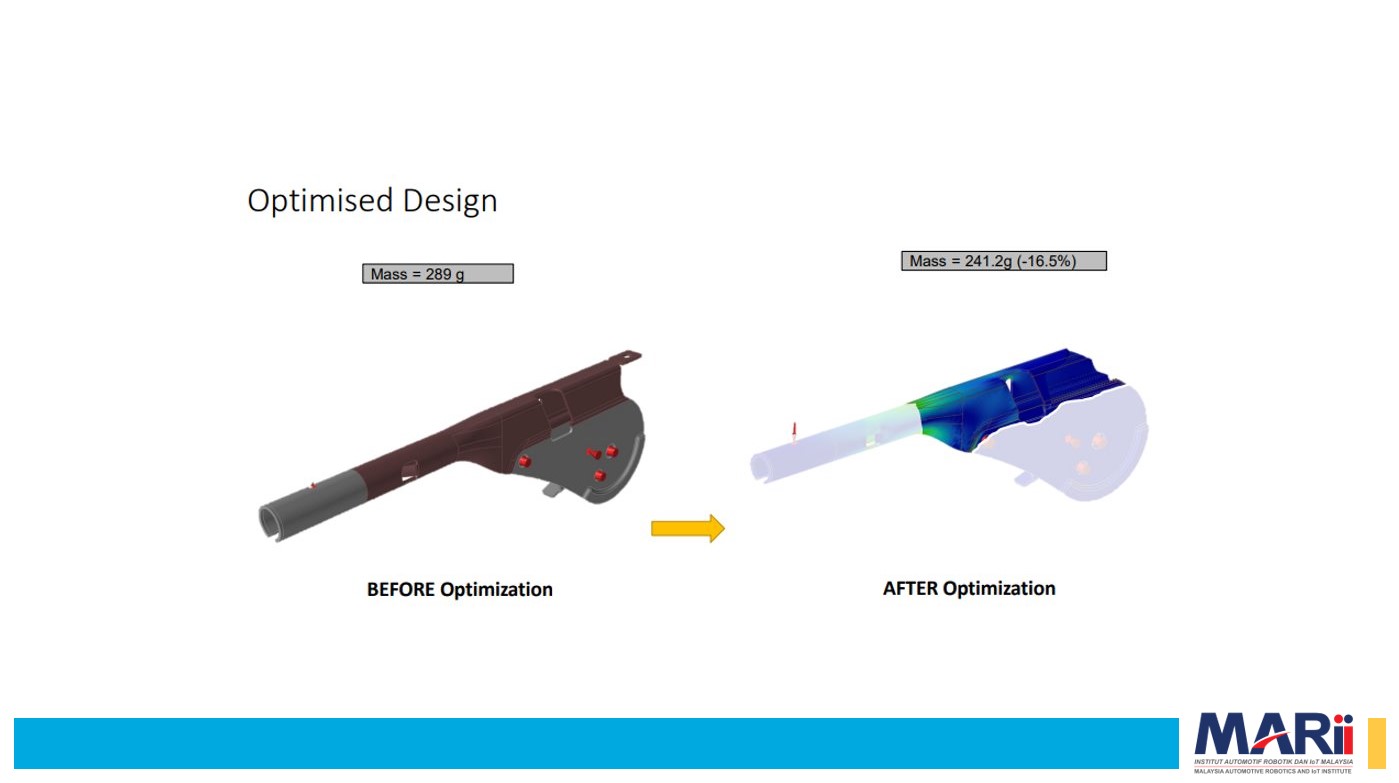

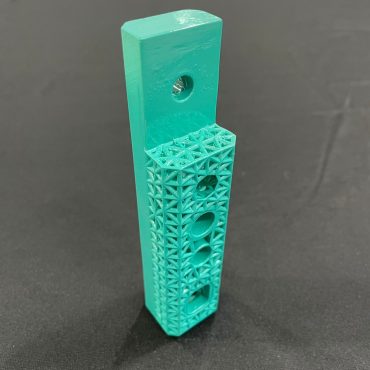

The figure represents a part named Handbrake Lever designed in Catia V5. Then it is optimized using Altair Inspire. Topology optimization can be used whenever you need to improve an existing design or design a brand new part which needs to fit in a specific space, be lightweight and withstand certain forces. It works by taking a block of material and shaping it by removing material, minimizing or maximizing part mass, displacement or compliance to fulfil set limits such as maximum stiffness or amount of deformation allowed. The reduced weight gave great cost saving and benefits to the company and industry as a whole.

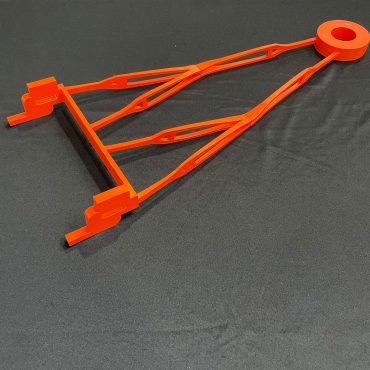

The optimized part is then prepared for 3D build using Materialise Magics and E-Stage. After printed, the part is then post-processed by sanding and coloring.